COMMERCIAL

REFRIGERATION

SYSTEMS

You can count on Admiral’s quality, dependability, and experiences

as your full-service refrigeration partner with commercial systems.

The KEY Ingredients

that form the foundation of Admiral Commercial Refrigeration Systems

Our Reputation For QUALITY

is built from a proven process that ensures success

1

Design and Engineering

To build a state-of-the-art refrigeration system, you need exceptional design and engineering. Our engineers and draftsmen use the latest CAD programs to bring our products to life. Only after the design is proven to meet our expectation is it then moved into fabrication.

1

Design and Engineering

To build a state-of-the-art refrigeration system, you need exceptional design and engineering. Our engineers and draftsmen use the latest CAD programs to bring our products to life. Only after the design is proven to meet our expectation is it then moved into fabrication.

Design and Engineering

3

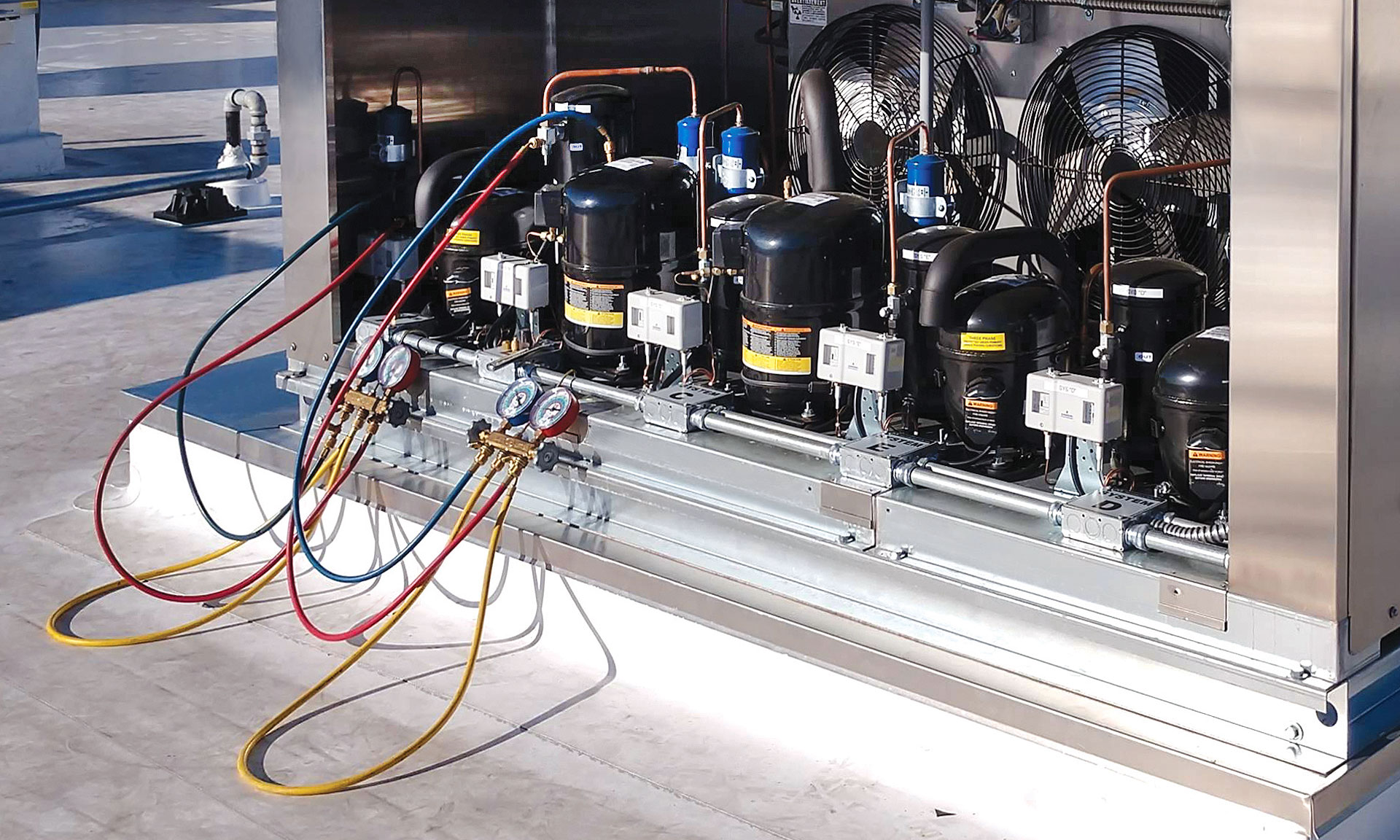

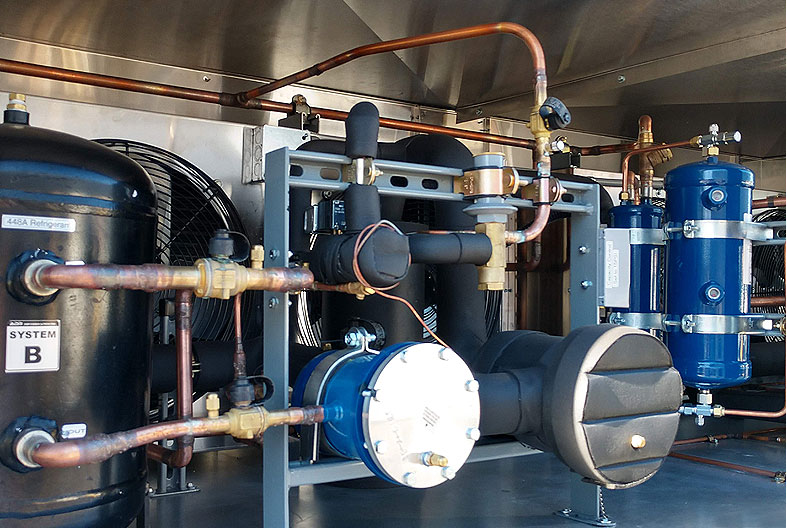

System Assembly and Testing

Our refrigeration assembly team inspects and tests every component in the system for optimum efficiency and performance. This level of craftsmanship and attention to detail has resulted in customer comments such as "this isn't a refrigeration system, this is art."

3

System Assembly and Testing

Our refrigeration assembly team inspects and tests every component in the system for optimum efficiency and performance. This level of craftsmanship and attention to detail has resulted in customer comments such as "this isn't a refrigeration system, this is art."

System Assembly and Testing

2

In-House Metal Fabrication

Our in-house metal fabrication department allows us to make sure that every product is built 100% to our standards. Our Amada 3500 Watt CNC CO2 laser cutter, automated press brake, welding stations, and experienced craftsman allow for precision when fabricating parts for a custom refrigeration system.

2

In-House Metal Fabrication

Our in-house metal fabrication department allows us to make sure that every product is built 100% to our standards. Our Amada 3500 Watt CNC CO2 laser cutter, automated press brake, welding stations, and experienced craftsman allow for precision when fabricating parts for a custom refrigeration system.

In-House Metal Fabrication

4

System Installation

Our veteran team applies the same industry expertise to this process as we do product design and construction. This allows us to anticipate potential challenges, so that we can avoid issues and obstacles, helping to ensure a smooth and timely installation of your refrigeration system.

4

System Installation

Our veteran team applies the same industry expertise to this process as we do product design and construction. This allows us to anticipate potential challenges, so that we can avoid issues and obstacles, helping to ensure a smooth and timely installation of your refrigeration system.

System Installation

Admiral System Strategies

Our refrigeration assembly team inspects and tests every component in the system for optimum efficiency and performance. This level of craftsmanship and attention to detail combined with our depth of experience and versatility is what sets all of our refrigeration systems apart from the rest.

LEARN MORE ABOUT OUR SYSTEMS

Admiral develops their cooling systems with an emphasis

on energy efficiency, and utilizes refrigerants that meet

or exceed EPA requirements. This attention to detail

ensures that your system is cost-effective to run, and is environmentally sustainable.

Made in the USA

Testimonials

We Work for the BEST

At Admiral, we value our relationships and our partnerships more than anything, Craftsmanship and care are put in every project we do, and we especially appreciate the trust that our clients have for our work. Contact us today for more details about how Admiral Refrigeration can make your next project a success!